Welding is an essential skill in many industries, from construction to automotive manufacturing. One key component of successful welding is choosing the right type of welding wire. With various options available, understanding the differences between them can greatly impact the quality of your welds. In this article, we’ll delve into the different types of welding wires, including their uses and advantages, to help you make the best choice for your welding projects.

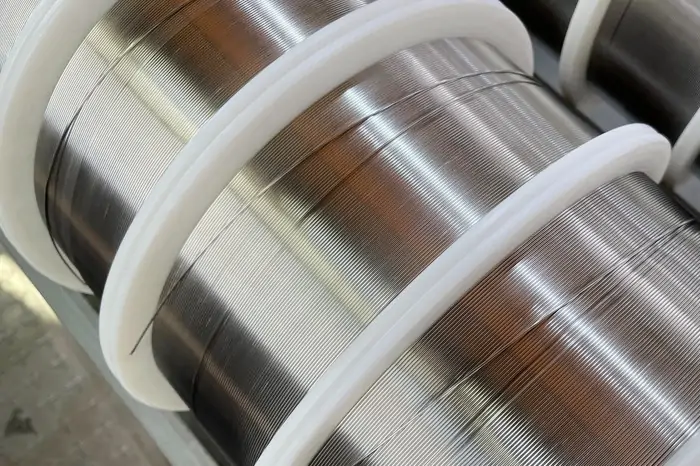

Welding wires are consumables used in the welding process to join two pieces of metal. They act as a filler material that helps create a strong bond between the base metals. The choice of welding wire depends on several factors, such as the type of metal being welded, the welding process, and the desired properties of the final weld.

Table of Contents

ToggleTypes of Welding Wires

There are several types of welding wires, each designed for specific applications and welding processes. Let’s explore some of the most common types.

MIG Welding Wire

MIG (Metal Inert Gas) welding is a popular welding technique that uses a continuous wire feed as an electrode to join metals. MIG welding wires are typically made of mild steel, stainless steel, or aluminum, and are available in various diameters. These wires are known for their ease of use and ability to produce clean, strong welds.

Aluminum Welding Wire

Aluminum welding wires are specifically designed for welding aluminum and aluminum alloys. They are known for their excellent corrosion resistance and lightweight properties, making them ideal for applications in the aerospace and automotive industries. Common types of aluminum welding wires include ER4043 and ER5356, each with specific properties suited for different applications.

Flux Cored Wire

Flux-cored wires are a type of welding wire that contains a flux core, which helps protect the weld from contamination. These wires are popular in heavy fabrication industries due to their ability to produce high-quality welds in less-than-ideal conditions, such as windy environments. Flux-cored wires are available in self-shielded and gas-shielded varieties, with each type offering specific benefits and applications.

Stainless Steel Welding Wire

Stainless steel welding wires are used to weld stainless steel materials. These wires are known for their high corrosion resistance and strength, making them suitable for applications in the food processing, chemical, and pharmaceutical industries. Stainless steel welding wires are available in various grades, such as ER308L and ER316L, each offering unique properties for different welding needs.

Nickel Alloy Welding Wire

Nickel alloy welding wires are used for welding nickel-based alloys, which are known for their high strength and resistance to corrosion and heat. These wires are often used in industries that require materials to withstand extreme conditions, such as chemical processing and power generation. Nickel alloy welding wires offer excellent weldability and versatility.

TIG Welding Wire

TIG (Tungsten Inert Gas) welding wires, also known as filler rods, are used in TIG welding processes. These wires are typically made of stainless steel, aluminum, or mild steel and are known for their ability to produce precise and clean welds. TIG welding is often used in applications where aesthetics and precision are important, such as in aerospace and artistic welding.

Solid Welding Wire

Solid welding wires are a type of wire without any flux core or coating. They are commonly used in MIG welding and require an external shielding gas to protect the weld from contamination. Solid welding wires are known for their ability to produce clean and strong welds, making them suitable for various applications.

Choosing the Right Welding Wire

Selecting the appropriate welding wire is crucial for achieving a high-quality weld. Here are some factors to consider when choosing a welding wire:

- Type of Metal: Consider the type of metal you will be welding. Different wires are designed for specific metals, such as aluminum, stainless steel, or nickel alloys.

- Welding Process: The welding process you plan to use, whether it’s MIG, TIG, or flux cored, will influence the type of wire you need.

- Mechanical Properties: Consider the desired properties of the final weld, such as strength, corrosion resistance, and ductility.

- Environment: The welding environment, such as indoor or outdoor conditions, may also impact your choice of welding wire, especially if you’re considering flux-cored wire.

Conclusion

Understanding the different types of welding wires and their applications can significantly impact the success of your welding projects. By selecting the right wire for your specific needs, you can ensure strong, clean, and durable welds. Whether you’re working with aluminum, stainless steel, or nickel alloys, there’s a welding wire designed to meet your requirements.

Remember to consider the type of metal, welding process, and desired properties of the weld when choosing your welding wire. With the right choice, you’ll be well-equipped to tackle any welding project with confidence.