Magnetization is a fundamental process that turns soft magnetic materials into essential components in various technologies, including transformers, inductors, and motors. Soft magnetic materials, characterized by their high magnetic permeability and low coercivity, are designed to enhance magnetic field strength with minimal energy loss. Let’s delve into the magnetization process of these materials and understand their unique properties.

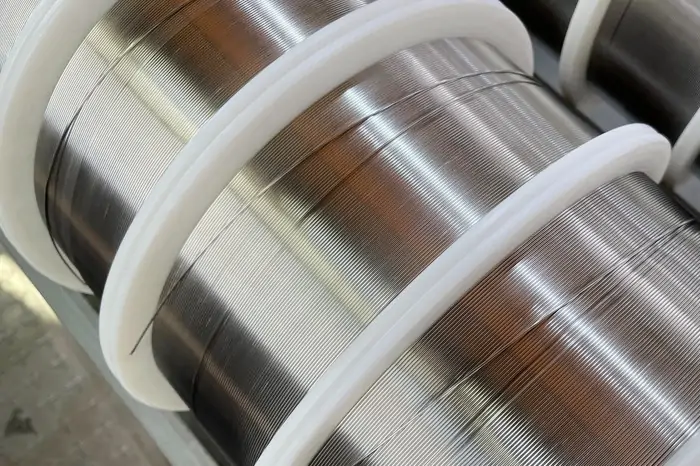

Soft magnetic materials are alloys that become magnetized easily and rapidly demagnetize when the external magnetic field is removed. The most common types include silicon steel, nickel-iron alloys, and soft ferrites. Their high magnetic permeability makes them ideal for use in applications requiring rapid and efficient magnetic field changes.

Initial Magnetization Curve

The magnetization process of soft magnetic materials begins with the initial magnetization curve. When an external magnetic field is applied, the magnetic domains within the material, which are initially oriented in random directions, start aligning parallel to the field. This alignment increases in the material’s magnetic field strength, reaching saturation when all domains are fully aligned.

Hysteresis Loop

The behavior of soft magnetic materials can be visualized using a hysteresis loop. As the external magnetic field strength increases, the material’s magnetization increases until it reaches saturation. Upon decreasing the field, the material does not immediately demagnetize but retains some residual magnetism, known as remanence. The loop is completed when the field is reversed, eventually reaching a point called coercivity, where the magnetization returns to zero.

Enhancing Magnetic Properties

The properties of soft magnetic materials can be optimized through various methods:

Alloying and Composition

The composition of soft magnetic materials plays a significant role in determining their magnetic properties. For instance, adding silicon to iron reduces energy loss, making it suitable for use in electrical transformers. Similarly, nickel-iron alloys, such as Permalloy, are known for their high magnetic permeability and are used in magnetic shielding and sensors.

Heat Treatment

Heat treatment is another technique used to enhance the magnetic properties of soft materials. By carefully controlling the cooling process, manufacturers can reduce internal stresses and improve the alignment of magnetic domains, resulting in higher permeability and lower coercivity.

Applications of Soft Magnetic Materials

Soft magnetic materials are integral to modern technology, found in devices ranging from power supplies to communication systems. Their ability to efficiently channel magnetic fields makes them ideal for applications requiring high-frequency response and low power loss.

Understanding the magnetization process of soft magnetic materials is crucial for optimizing their performance in various applications. By exploring the effects of composition, heat treatment, and magnetic field strength, engineers can design materials that meet the demands of today’s technological landscape.