Corrosion is an ever-present challenge in many industries, where materials are constantly exposed to harsh environments that can cause them to deteriorate. This is where corrosion-resistant alloys come into play. These materials are specifically designed to withstand the damaging effects of corrosion, ensuring longevity and reliability in various industrial applications. In this article, we will explore the different types of corrosion-resistant alloys and their industrial applications, providing insight into why they are indispensable in modern engineering.

Understanding Corrosion Resistance

Corrosion is a natural process that occurs when metals react with their environment, leading to the gradual degradation of the material. This process can be accelerated in industrial settings due to the presence of corrosive elements such as water, chemicals, and gases. Corrosion-resistant alloys are engineered to combat these effects, maintaining their integrity and performance over time.

Types of Corrosion-Resistant Alloys

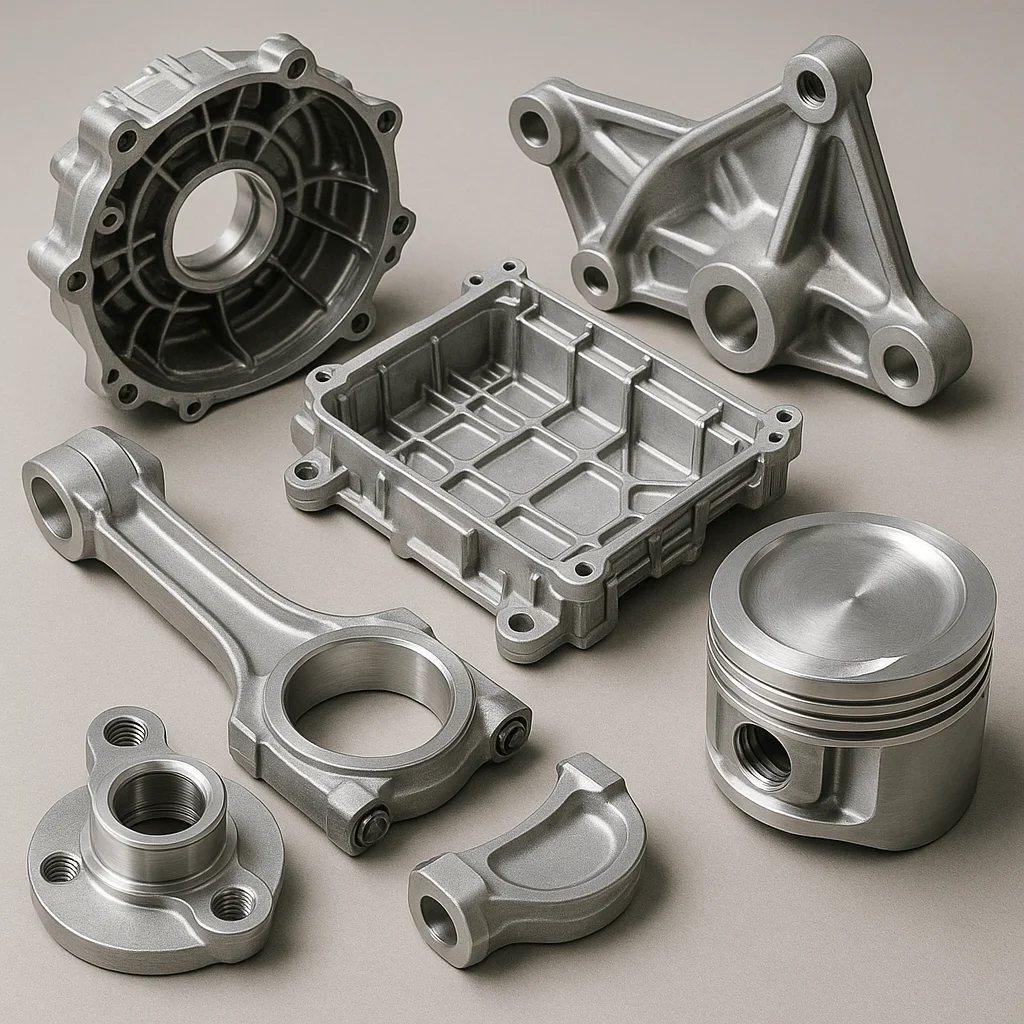

Several types of alloys are designed for corrosion resistance, each with unique properties suited to specific applications. These include:

- Stainless Steel: Known for its excellent resistance to rust and staining, stainless steel is used extensively across industries. Its corrosion resistance is due to the presence of chromium, which forms a passive film on the surface, preventing further corrosion.

- Aluminum Alloys: These are lightweight yet strong, making them ideal for applications where weight is a concern. Some aluminum alloys are specifically treated to enhance their resistance to corrosion, particularly in marine and aerospace environments.

- Nickel Alloys: These alloys are highly resistant to a variety of corrosive environments, including those with high temperatures and pressures. They are commonly used in chemical processing and power generation industries.

- Titanium Alloys: Known for their superior strength-to-weight ratio and corrosion resistance, titanium alloys are often used in aerospace, medical, and marine industries.

Applications of Corrosion-Resistant Alloys

The use of corrosion-resistant alloys spans multiple industries, each benefiting from the unique properties of these materials. Here are some key industrial applications:

Oil and Gas Industry

In the oil and gas sector, equipment is frequently exposed to harsh conditions, including saltwater, hydrogen sulfide, and carbon dioxide. Corrosion-resistant alloys such as stainless steel and nickel-based alloys are used in pipelines, valves, and offshore platforms to ensure durability and safety.

Chemical Processing

Chemical plants deal with highly corrosive substances that can quickly degrade standard materials. Corrosion-resistant alloys like Hastelloy and Inconel are essential in constructing reactors, heat exchangers, and storage tanks, where they can withstand aggressive chemical reactions.

Aerospace Industry

The aerospace industry requires materials that can handle extreme conditions, including high altitudes and rapid temperature changes. Corrosion-resistant aluminum alloys and titanium alloys are commonly used in aircraft frames and engine components, providing strength without adding unnecessary weight.

Marine Industry

Seawater is notoriously corrosive, making it essential to use materials that can withstand prolonged exposure. Stainless steel and aluminum alloys are widely used in shipbuilding, offshore drilling rigs, and other marine applications to prevent corrosion-related failures.

Power Generation

Power plants, especially those using fossil fuels or nuclear energy, operate under high temperatures and pressures. Corrosion-resistant alloys ensure the longevity and reliability of turbines, boilers, and other critical components in these demanding environments.

Medical Devices

In the medical field, implants and surgical instruments must resist corrosion to prevent adverse reactions in the human body. Titanium and stainless steel are frequently used in these applications due to their biocompatibility and resistance to bodily fluids.

Benefits of Using Corrosion-Resistant Alloys

The use of corrosion-resistant alloys offers several advantages:

- Longevity: These materials extend the lifespan of equipment, reducing the need for frequent replacements and maintenance.

- Safety: By preventing material degradation, corrosion-resistant alloys help maintain the structural integrity of critical components, enhancing overall safety.

- Cost-Effectiveness: Although initially more expensive, these alloys can lead to cost savings over time by minimizing repair and replacement costs.

- Environmental Protection: Reducing the need for replacements and repairs decreases resource consumption and waste, contributing to more sustainable practices.

Choosing the Right Alloy

Selecting the appropriate corrosion-resistant alloy depends on several factors, including the environment, temperature, pressure, and specific application requirements. It’s crucial to work with materials specialists and engineers to identify the best alloy for your needs, ensuring optimal performance and longevity.

Factors to Consider

- Environment: Determine the type of corrosive elements present and their concentrations.

- Mechanical Properties: Evaluate the strength, ductility, and toughness required for the application.

- Cost: Consider the budget and weigh it against the potential long-term savings from reduced maintenance and replacements.

Conclusion

Corrosion-resistant alloys play a vital role in modern industry, offering solutions to the pervasive problem of material degradation. By understanding their properties and applications, industries can make informed decisions that enhance performance, safety, and sustainability. Whether in oil and gas, aerospace, or medical fields, the strategic use of these materials ensures that equipment can withstand the test of time and harsh conditions.

Incorporating corrosion-resistant alloys into your industrial processes is a proactive step towards achieving long-term efficiency and reliability. As technology advances, these materials will continue to evolve, offering even greater resilience and opportunities for innovation.