High temperature oxidation is a critical factor when considering materials for high-heat applications, especially in industries like aerospace and power generation. Nickel-based alloys, known for their exceptional strength and resistance to heat, are often the material of choice. Understanding how these alloys perform under extreme conditions is crucial for ensuring safety and efficiency.

Table of Contents

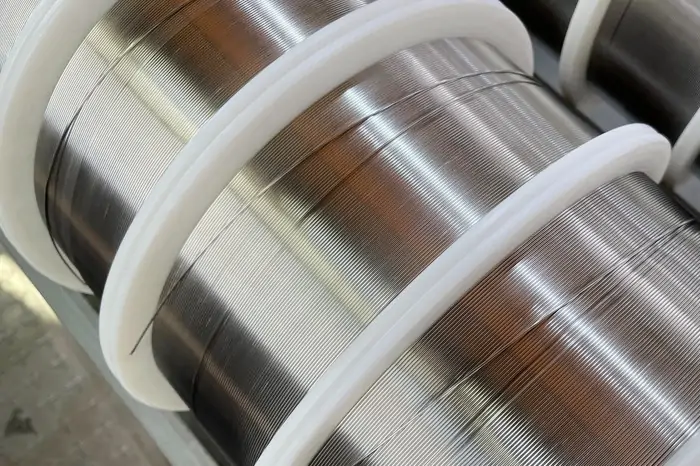

ToggleNickel-based alloys, such as Inconel, are specially designed to withstand high temperatures and corrosive environments. These alloys are composed primarily of nickel, along with elements like chromium, iron, and molybdenum. This unique combination provides outstanding oxidation resistance, making them ideal for use in high-temperature settings.

Understanding High Temperature Oxidation

High-temperature oxidation refers to the reaction between a metal and oxygen at elevated temperatures, leading to the formation of an oxide layer on the metal’s surface. While this layer can sometimes provide a protective barrier, excessive oxidation can degrade the material, compromising its structural integrity.

Oxidation Resistance in Nickel Alloys

Nickel alloys are lauded for their oxidation resistance. The presence of chromium in these alloys is particularly beneficial, as it forms a stable oxide layer that shields the underlying material from further oxidation. This protective layer is crucial in preventing rapid material degradation in high-temperature environments.

Applications of Nickel Alloys in High Heat

Nickel-based alloys are widely used in applications that demand high-temperature resilience. These include turbine blades in jet engines, nuclear reactors, and chemical processing equipment. The ability of these alloys to maintain their strength and resist oxidation under intense heat makes them invaluable in such critical applications.

Challenges and Considerations

Despite their benefits, nickel-base alloys are not immune to challenges. Prolonged exposure to extreme conditions can lead to issues such as grain boundary oxidation, which can weaken the material over time. Therefore, understanding the specific requirements of your application is essential when selecting the appropriate alloy.

Enhancing Oxidation Resistance

Research and development continue to focus on enhancing the oxidation resistance of nickel alloys. Innovations in alloy composition and surface treatments are being explored to extend the lifespan of these materials in harsh environments. Such advancements ensure that nickel-base alloys remain at the forefront of high-temperature applications.

Conclusion

In conclusion, nickel-base alloys are indispensable in industries where high temperature and corrosion resistance are paramount. Their ability to withstand oxidation and maintain structural integrity under extreme conditions makes them a critical component in modern engineering. As technology advances, so too will the capabilities of these remarkable materials, ensuring their continued relevance in high-heat applications.

For those seeking materials that offer unparalleled performance in challenging environments, nickel-base alloys are an excellent choice. Their proven track record and ongoing advancements make them a reliable option for high-temperature applications.