In the world of manufacturing, precision and durability are key. Alloy steel precision casting offers the ideal solution for industries requiring high-strength and detailed components. This method, known for producing precise and intricate parts, is essential for various applications. Here, we’ll delve into the advantages of alloy steel precision casting and why it stands out in the field of metal casting.

Table of Contents

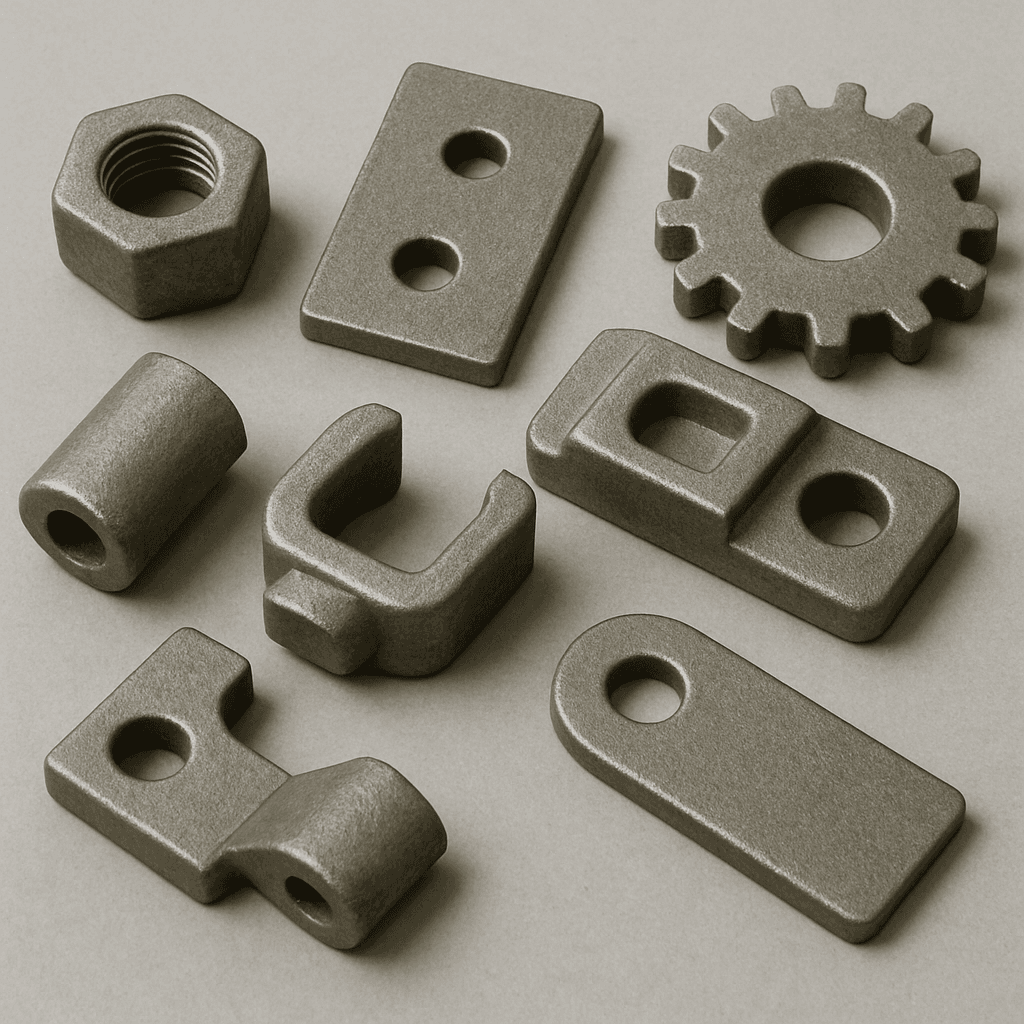

ToggleAlloy steel precision casting, often referred to as investment casting, is a process that involves creating components by pouring molten alloy steel into a mold that precisely shapes the part. This method is widely used in industries such as automotive, aerospace, and machinery, offering unmatched precision and quality.

Key Advantages of Alloy Steel Precision Casting

High Precision and Accuracy

One of the most significant benefits of alloy steel precision casting is its ability to produce parts with intricate shapes and fine details. The precision casting process allows manufacturers to achieve tight tolerances, ensuring that each component meets exact specifications. This high level of accuracy is crucial for industries that demand reliability and performance in their products.

Superior Strength and Durability

Alloy steel cast parts are known for their exceptional strength and resilience. The use of alloy steel in precision casting results in components that can withstand heavy loads, high pressure, and extreme temperatures. This makes them ideal for industrial applications where durability is paramount, such as in heavy machinery and automotive engines.

Versatility and Customization

Precision casting offers immense versatility, allowing for the production of custom steel castings tailored to specific needs. Whether it’s for OEM precision cast parts or unique designs, manufacturers can create a wide range of components with varying sizes and complexities. This flexibility makes alloy steel precision casting suitable for a diverse array of industries and applications.

Cost-Effectiveness

Applications of Alloy Steel Precision Casting

The versatility and reliability of alloy steel precision casting make it an attractive choice for a variety of applications. These include:

- Automotive Components: Used in engine parts, transmission components, and suspension systems.

- Aerospace Parts: Essential for producing lightweight and durable components for aircraft.

- Industrial Machinery: Vital for creating robust parts that withstand harsh operational conditions.

In conclusion, alloy steel precision casting stands out as a premier method for producing high-strength, precise, and durable components. Its advantages in precision, strength, versatility, and cost-effectiveness make it an invaluable process for industries seeking reliable and efficient solutions. Whether you are an OEM looking for precision cast parts or a manufacturer in need of custom steel castings, alloy steel foundries provide a dependable option for your production needs.