Copper welding wires are a crucial component in the welding industry, known for their unique properties that provide numerous benefits across various applications. Whether you’re a seasoned welder or a beginner exploring different materials, understanding the advantages of using copper welding wires can significantly enhance your work. In this article, we will delve into the benefits of copper welding wires, explore their applications, and understand why they are a preferred choice for many professionals.

Table of Contents

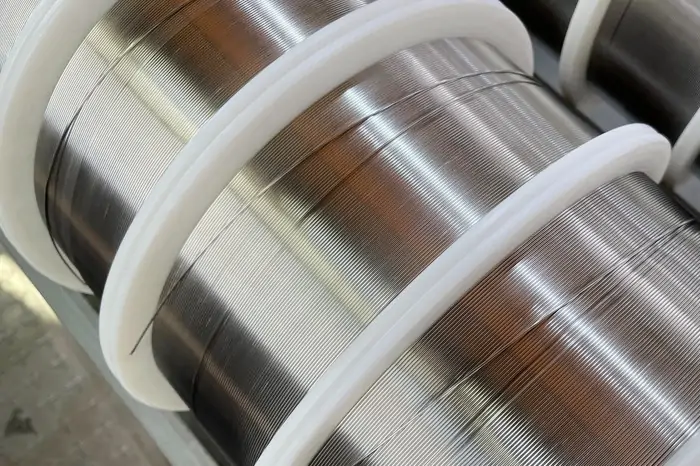

ToggleWhat Are Copper Welding Wires?

Copper welding wires are rods or wires made from copper or copper alloys used in various welding processes. They serve as a filler material that helps join two metal pieces together by melting and solidifying to form a strong bond. Copper welding wires are particularly popular due to their excellent conductivity, corrosion resistance, and versatility.

Types of Copper Welding Wires

There are several types of copper welding wires, each designed for specific applications. Understanding these types can help you choose the right wire for your project.

- Copper Welding Rods: These are solid rods used in gas welding and brazing processes. They are ideal for joining copper and brass materials.

- MIG Welding Copper Wire: This type of wire is used in Metal Inert Gas (MIG) welding, a process that uses a continuous wire feed to create a weld. MIG welding copper wire is known for its smooth feedability and strong welds.

- Copper Filler Wire: Used in both MIG and TIG (Tungsten Inert Gas) welding, copper filler wire is essential for filling gaps and creating strong joints in copper-based materials.

Advantages of Copper Welding Wires

Copper welding wires offer several advantages that make them a popular choice in the welding industry. Here are some key benefits:

Excellent Conductivity

Copper is renowned for its superior electrical and thermal conductivity. This property is crucial in welding as it ensures efficient energy transfer, resulting in faster welding speeds and reduced energy consumption. This can be particularly beneficial in applications requiring high electrical conductivity, such as electrical components and wiring systems.

Corrosion Resistance

Copper and its alloys exhibit excellent resistance to corrosion, making them ideal for use in harsh environments. This resistance ensures that welds made with copper welding wires remain strong and durable over time, even when exposed to moisture, chemicals, or extreme weather conditions. This makes copper welding wires suitable for outdoor applications and marine environments.

Versatility

Copper welding wires are incredibly versatile and can be used in a wide range of welding applications. Whether you’re working with copper, brass, or even dissimilar metals, copper welding wires can provide a reliable and strong joint. This versatility makes them a valuable addition to any welder’s toolkit.

Strong and Durable Joints

Welds made with copper welding wires are known for their strength and durability. The material’s inherent properties ensure that the joints withstand significant stress and strain, making them suitable for structural applications. This strength is particularly important in industries such as construction and automotive manufacturing, where reliability is paramount.

Reduced Spatter

One of the challenges in welding is dealing with spatter, which can lead to a messy workspace and require additional cleaning. Copper welding wires produce minimal spatter, resulting in cleaner welds and less post-weld cleanup. This not only saves time but also improves the overall quality of the weld.

Applications of Copper Welding Wires

Copper welding wires are used in various industries due to their unique properties and benefits. Here are some common applications:

Electrical Industry

Copper’s excellent conductivity makes it the material of choice for electrical applications. Copper welding wires are used to join electrical components, create wiring systems, and manufacture transformers and other electrical devices. Their conductivity ensures efficient energy transfer and reliable electrical connections.

Plumbing and HVAC Systems

Copper is commonly used in plumbing and HVAC (Heating, Ventilation, and Air Conditioning) systems due to its corrosion resistance and thermal conductivity. Copper welding wires are used to join pipes and fittings, ensuring leak-proof and durable connections.

Automotive Industry

In the automotive industry, copper welding wires are used to join various components, including radiators, fuel lines, and electrical systems. Their strength and durability make them ideal for withstanding the demands of automotive applications.

Marine and Aerospace Industries

The corrosion resistance of copper welding wires makes them suitable for use in the marine and aerospace industries. They are used to join components exposed to harsh environments, ensuring reliable performance over time.

Choosing the Right Copper Welding Wire

Selecting the right copper welding wire for your project involves considering several factors, including the type of metal you’re working with, the welding process, and the specific requirements of your application.

Consider the Metal Type

Different metals require different welding wires. When working with copper or copper alloys, ensure that you choose a wire specifically designed for those materials. This ensures compatibility and optimal performance.

Match the Welding Process

The welding process you choose will also determine the type of copper welding wire you need. For MIG welding, select a wire designed for MIG applications. Similarly, for TIG welding, choose a suitable copper filler wire.

Consult with Suppliers

Copper welding wire suppliers can provide valuable insights and recommendations based on your specific needs. They can help you choose the right wire type, diameter, and composition to achieve the best results for your project.

Conclusion

Copper welding wires offer numerous advantages, including excellent conductivity, corrosion resistance, versatility, and the ability to create strong, durable joints. These properties make them a preferred choice for various applications across industries, from electrical and plumbing to automotive and aerospace. By understanding the benefits and applications of copper welding wires, you can make informed decisions and enhance the quality and efficiency of your welding projects.

Whether you’re a professional welder or a DIY enthusiast, incorporating copper welding wires into your work can lead to superior results and long-lasting performance. Consider the specific needs of your project, consult with suppliers, and choose the right copper welding wire to achieve the best outcomes.