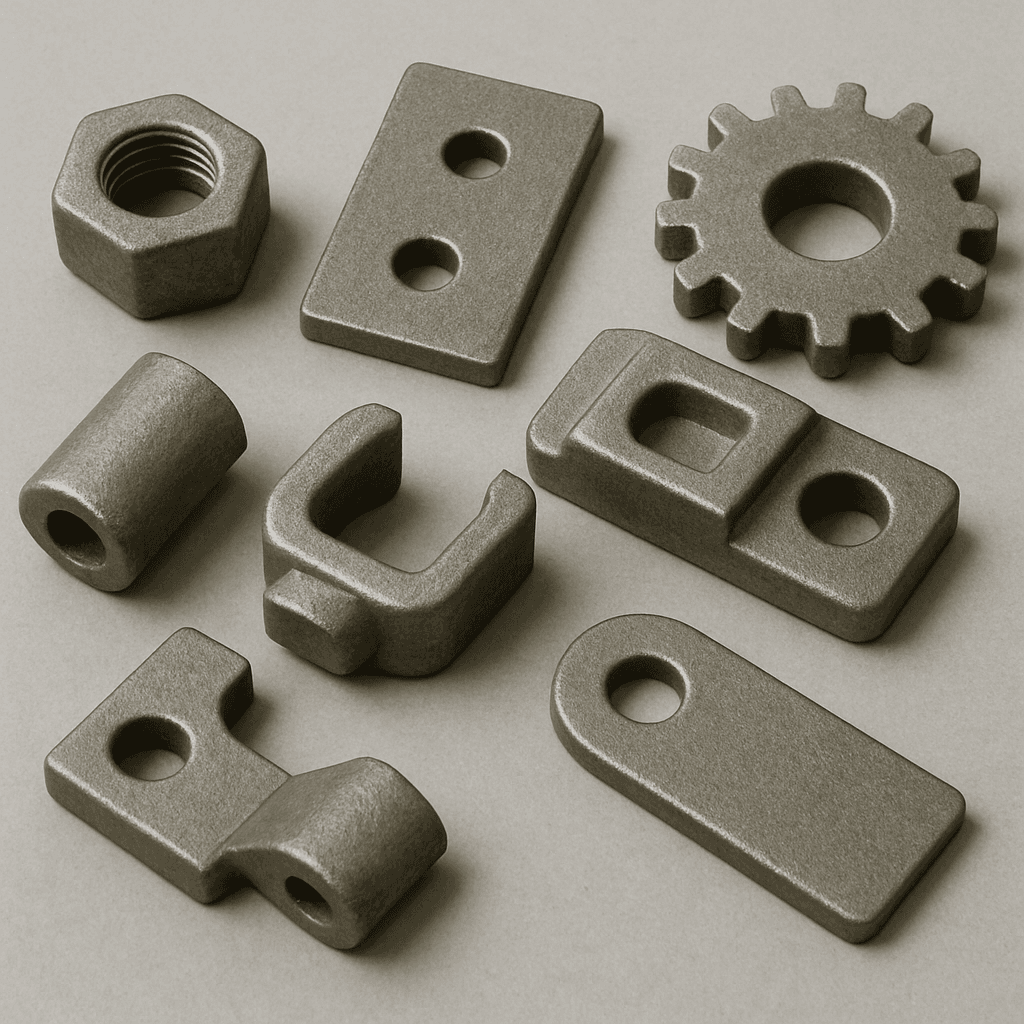

In the world of metal fabrication, alloy steel precision casting techniques stand out for their remarkable ability to produce high-strength, durable components with intricate designs. This method has revolutionised how parts are manufactured, offering several advantages over traditional methods. Let’s delve into the manifold benefits of alloy steel precision casting techniques and understand why they are integral to modern manufacturing processes.

Table of Contents

ToggleUnderstanding Alloy Steel Precision Casting

Before we explore the benefits, it’s crucial to understand what alloy steel precision casting involves. This process, also known as investment casting, involves creating a wax model of the desired component, which is then coated with a ceramic material. Once the ceramic hardens, the wax is melted away, leaving a mold. Molten alloy steel is then poured into this mold to form the part.

The Steel Casting Process

The steel casting process is essential in creating complex and custom steel parts. The wax models used in precision metal casting are exact replicas of the final component, ensuring precision and consistency in every part manufactured.

- Creating the Wax Pattern: The first step in the precision casting process involves crafting a wax pattern of the item. This pattern is an exact model of the part to be produced.

- Creating the Ceramic Mold: The wax pattern is coated with a refractory ceramic material, forming a shell around it. This step is critical as it defines the precision and finish of the final product.

- Wax Removal: The ceramic shell is heated to remove the wax, leaving a hollow mold ready for metal pouring.

- Pouring the Alloy Steel: The molten alloy steel is poured into the ceramic mold. Once it cools and solidifies, the ceramic shell is broken away, revealing the precision-cast component.

- Finishing Touches: Finally, the cast part undergoes finishing processes like grinding, machining, or heat treatment to meet the desired specifications.

Advantages of Alloy Steel Precision Casting

Now that we understand the process, let’s discuss the advantages that make alloy steel precision casting a preferred choice in various industries.

High-Strength Steel Components

One of the primary benefits of using alloy steel in precision casting is the creation of high-strength components. Alloy steel is known for its robustness and durability, making it ideal for parts that must withstand significant stress and wear.

The ability to cast high-strength steel components with precision ensures that industries such as automotive, aerospace, and construction have reliable and resilient parts for their machinery and structures.

Versatility in Design

Precision casting allows for highly intricate designs that would be impossible or costly to achieve with traditional manufacturing methods. The flexibility in design means that complex geometries can be created without compromising strength or integrity.

This versatility is particularly beneficial in industries that require custom steel casting solutions to meet specific functional and aesthetic requirements. From turbine blades to medical devices, the precision casting process accommodates a wide range of applications.

Cost-Effectiveness

While the initial setup for alloy steel precision casting might seem higher than some traditional methods, the long-term cost-effectiveness is significant. The reduction in material waste, combined with the ability to produce complex parts in a single piece, reduces the need for additional assembly and welding, thereby cutting down labor and production costs.

Furthermore, the precision of the casting process minimizes the need for secondary machining, which can be both time-consuming and expensive.

Enhanced Surface Finish

The ceramic mold used in precision casting provides a smooth surface finish on the final component. This is particularly advantageous in applications where surface quality is critical, such as in aesthetic or aerodynamic components.

The refined surface finish reduces the need for extensive post-casting machining or polishing, further saving time and costs in the production process.

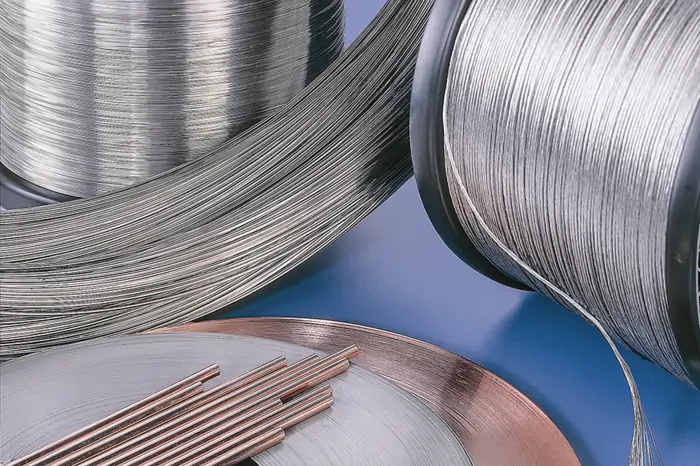

Reduction in Material Waste

The precision involved in the investment casting steel process ensures that the exact amount of material needed is used for each part. This efficiency not only reduces material waste but also leads to more sustainable manufacturing practices.

Reducing waste is not just beneficial for cost-saving but is also an essential aspect of environmentally responsible manufacturing.

Applications of Precision Casting Alloy Steel

Alloy steel precision casting is utilized across various industries due to its adaptability and efficiency. Here are some of the key sectors benefiting from this technique:

Automotive Industry

In the automotive sector, precision casting is used to produce engine components, transmission parts, and structural components. The high-strength and durability of alloy steel ensure that these parts can withstand the rigorous demands of vehicle operation.

Aerospace Industry

The aerospace industry relies on precision casting for components such as turbine blades, structural components, and landing gear parts. The ability to produce lightweight yet strong parts is crucial for aircraft performance and safety.

Medical Equipment

Precision casting is used to manufacture various medical devices and equipment, including surgical instruments and implants. The precision and quality of the surface finish are vital for ensuring the safety and efficacy of medical products.

Construction Machinery

Construction machinery requires robust and reliable components to operate effectively. Precision casting provides the necessary strength and durability for parts used in heavy equipment and machinery.

Conclusion

Alloy steel precision casting techniques offer numerous advantages that make them indispensable in modern manufacturing. From creating high-strength steel components to offering cost-effective, versatile design solutions, precision casting is a cornerstone of innovation in various industries.

By understanding the process and benefits of alloy steel precision casting, manufacturers can make informed decisions to enhance their production capabilities, improve product quality, and achieve greater efficiency.

In an era where precision, durability, and cost-efficiency are paramount, alloy steel precision casting stands as a testament to the advancements in metal fabrication technology.

Whether you’re in the automotive, aerospace, medical, or construction industry, incorporating precision casting into your production strategy can lead to significant improvements in product performance and cost savings. As industries continue to demand more complex and high-quality components, the role of precision casting will undoubtedly continue to grow.