In the world of industrial machining, alloy steel is a fundamental material that plays a crucial role. Known for its high strength and durability, alloy steel is a popular choice for precision machining. This article delves into the importance of alloy steel in creating precision-machined parts and why it stands out in the field of metal fabrication.

Table of Contents

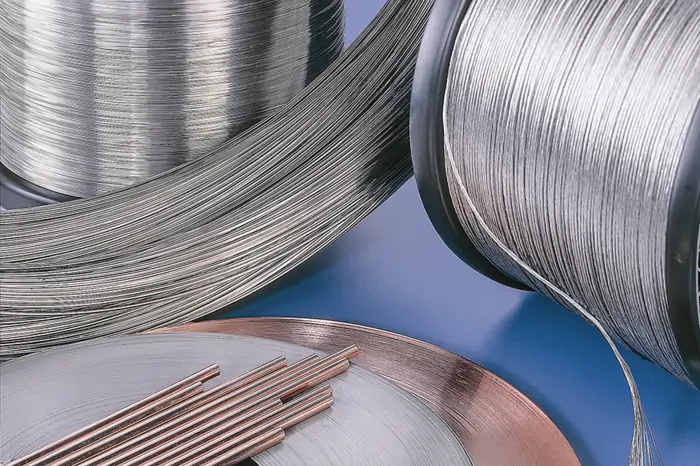

ToggleAlloy steel is a type of steel that has been mixed with other elements to improve its mechanical properties. These elements can include manganese, nickel, chromium, and vanadium. The addition of these materials enhances the steel’s strength, hardness, wear resistance, and toughness, making it ideal for producing high-strength components.

The Role of Alloy Steel in Precision Machining

Precision machining involves removing material from a workpiece to create a specific shape or design. This process requires materials that can withstand stress and maintain their structural integrity. Alloy steel is perfect for this because of its ability to endure high levels of pressure and heat without deforming.

Benefits of Using Alloy Steel in Machined Parts

High Strength and Durability

One of the main reasons alloy steel is favored in industrial machining is its high strength. The added elements in alloy steel contribute to its enhanced mechanical properties, making it suitable for high-stress applications. This strength ensures that the machined steel parts can withstand demanding environments and prolonged use without deteriorating.

Versatility in Applications

Alloy steel’s versatility is another reason it’s widely used in precision machining. It can be crafted into various custom metal parts, from simple mechanical components to complex CNC-machined parts. Its adaptability makes it valuable in numerous industries, including automotive, aerospace, and construction.

Enhanced Wear Resistance

The wear resistance of alloy steel is significantly improved through the addition of elements like chromium and nickel. This characteristic is critical in applications where the components face friction and wear over time. Alloy steel precision-machined parts maintain their quality and functionality longer than many other materials.

Common Applications of Alloy Steel Parts

Automotive Industry

In the automotive sector, alloy steel is often used for parts that require high strength and precision. Components such as gears, shafts, and engine parts are typically made from alloy steel to ensure reliability and performance.

Aerospace Industry

The aerospace industry demands materials that can perform under extreme conditions. Alloy steel is used to fabricate parts like landing gear, engine components, and structural elements, all of which require precision and durability.

Construction and Heavy Machinery

Alloy steel’s robustness makes it ideal for construction and heavy machinery applications. It’s used in the production of cranes, bulldozers, and other equipment that need to support heavy loads and withstand harsh working conditions.

The Precision Machining Process

CNC Machining and Its Importance

Computer Numerical Control (CNC) machining is a process that uses computers to control machine tools. CNC machining is essential in creating precision-machined components from alloy steel because it allows for high accuracy and repeatability. This precision is crucial in industries where even the smallest error can lead to significant issues.

Fabrication Techniques

Metal fabrication techniques such as milling, turning, and drilling are commonly used in precision machining. These processes involve cutting away material to create the desired shape. The toughness of alloy steel makes it suitable for these techniques, ensuring that the final product meets the required specifications.

Choosing the Right Alloy Steel for Your Project

When selecting alloy steel for precision machining projects, consider factors such as the specific mechanical properties required, the environment in which the part will be used, and the cost implications. Different alloy steels offer varying levels of strength, corrosion resistance, and machinability, so it’s important to choose the one that aligns with your project needs.

Working with a Professional Machining Partner

Partnering with a skilled machining service provider can ensure that your alloy steel parts are manufactured to the highest standards. A professional team will have the expertise and equipment necessary to handle complex projects and deliver components that meet your specifications.

Conclusion

Alloy steel is an indispensable material in the field of precision machining, offering unmatched strength, durability, and versatility. Its ability to be transformed into high-strength components makes it an excellent choice for a wide range of industrial applications. By understanding the benefits and applications of alloy steel, you can make informed decisions for your next machining project.

Precision machining with alloy steel guarantees parts that not only meet but also exceed industry standards, providing reliability and performance across various sectors. Whether you’re in automotive, aerospace, or construction, alloy steel machined parts are sure to enhance the quality and efficiency of your operations.